NJQRP

Sniffer

CONSTRUCTION

TIPS

Answers to some common questions that have come in ...

1)

I'm confused about which

leads of C1 (the variable tuning capacitor) should be used.

First,

snip off the leads from the side the capacitor containing 4 leads

You

will USE the leads coming from the side of the capacitor containing 5 leads, as

shown below. Nip off the bottom left and bottom right leads, and use the

remaining three leads (marked as 1, 2 and 3). Lead #2 is the common point

between the dual internally-ganged capacitors and should be connected to L2, C2

and the antennas, as indicated in the schematic.

2) Looking at the

Parts Layout template in the directions, I see a number of places where

it seems as if two or more components are tied together, but have separate pads.

For example, at the junction of R12, LED-1, M1 and D3, it would be possible

for them to meet at a common point, but three pads are used. Is this just to

make the layout prettier, or more open? Do you use a small jumper wire to

connect them?

Yes, "multiple pads tied together" are

used primarily to help the builder by having a more open layout. A

purist (with a steady hand) could indeed reduce the pad count and have a more

compact layout. But a greater chance of success exists with a more open

layout as suggested. (And don't forget that this was just my personal

suggestion for a layout ... use whatever layout or configuration makes you

comfortable!)

3) The Layout

template also shows pads being used for places where the component lead goes

to ground. Wouldn't these leads just get soldered to the ground plane, with no

pad?

Yes. I've found the approach of using a pad even

for grounded leads is convenient in that it allows me later to easily

"lift" the component from ground should I need to add another in

series or perhaps to measure the current through that lead to ground.

Again, builder's preference!

4) I got the

Islander Pad Cutter and I'm ready to start making the pads. Do I have to

use a drill press like the instruction sheets with the Pad Cutter suggests?

You'll have the best success in using the Pad

Cutter if you can hold it steady and at 90-degrees to the plane of the

copper-clad board being cut. I usually chuck the Pad Cutter into a small

drill press (e.g., $65 from Home Depot) and lay the board flat on the plate

just inches beneath the end of the cutter. I'm then able to drill all

the pads in the copper-clad within 5 minutes merely by working the

fast-turning bit down and up for each of the locations. I've also

successfully used the Pad Cutter when chucked up in a Dremel hobby tool, using its

$10 "drill stand" accessory that I picked up at a local hardware

store. Again, the key to success in using the Pad Cutter is to use high

speed and to use it at 90-degrees to the board being cut.

5) Do I have to

use the Pad Cutter to make the Manhattan-style circuit nodes in the Sniffer

Kit?

No, you could easily nip off small pieces of the

thin copper-clad strips supplied in the kit to make standard little

rectangular pads that you'd Super-Glue to the surface of the copper-clad

board. Then just solder the component leads to the pads as described in the

Construction section of the manual.

6) How did you

hold the 9V battery down in your prototype Sniffer?

I drilled holes in the copper-clad board on each

side of the outline for the battery. Then I used two Tie-Wraps ganged together

(to get the required length) to go around the battery and through the holes in

the board. They are pulled tight and joined bottom side of the board.

This is a neat technique in that the Tie-Warps hold the battery tight enough,

yet they allow the battery to be slipped out for replacement. (Or during

travel, as I found out ... the TSA agents at the airport certainly didn't like the

Sniffer in my carryon!)

7) I broke one of

the germanium diodes and had to use a replacement from my junk box, but found

that I couldn't get the unit to operate correctly. The meter couldn't be

zeroed with the balance trim pot. Yet I tried another diode and it

worked okay. What's happening?

The diodes supplied in the kit are all from the

same "batch" and their junction characteristics are all pretty

close, as they need to be when used in a bridge configuration as in the

Sniffer. When the junction characteristics vary greatly (i.e., if their

forward voltage drops are significantly different), the trim pot may not have

enough adjustable range to balance out the bridge and a uncorrectable plus or

minus offset will be seen in the meter reading. The same condition could

also conceivably happen with the two red LEDs. A simple check of forward

voltage drop for any replacements diode could be done to ensure that it's in

the same ballpark at the one already being used. You don't need to be

too concerned about having a "precisely matched pair" of diodes, as

the design is not that sensitive.

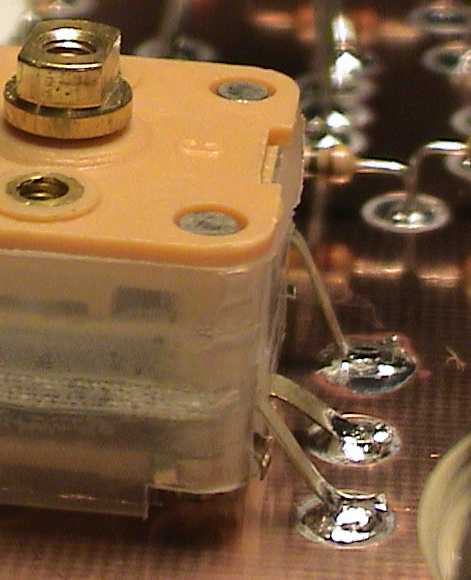

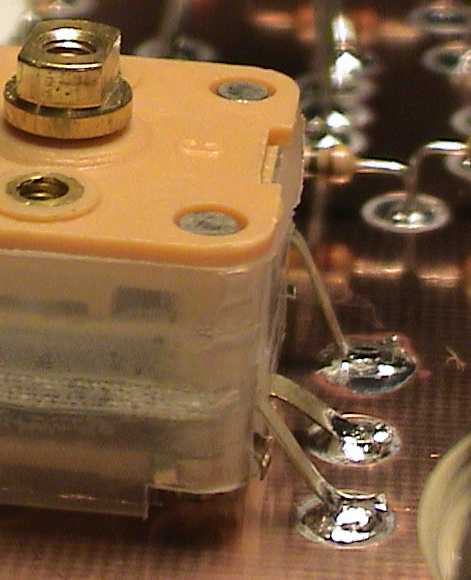

8) I saw someplace

that when you lay toroidal inductors close against a ground plane, the circuit

performance is affected. Yet the photo of your Sniffer on the website

shows them laying flat on the copper-clad. What's sacrificed by mounting

them this way.

You're right. When mounted this way the

tuned circuit's Q is lowered, making the circuit less sensitive and less

selective. Although the Sniffer worked pretty well as-is, it might even

be better if I were to peel away the copper-clad material underneath the

toroids, or perhaps mount the toroids in a "stand-up" manner.

Even better yet, a Sniffer seen at a recent NJQRP meeting had them glued right

to the side of the polyvaricon tuning capacitor C1, providing nice short leads

and a solid, non-metallic mounting surface. Builder's choice!

Last Modified: July 18, 2003

![]()

![]()

![]()